1. MOUNTING

Check your mounting

It is your lathe station or CNC-machine, that decides which mounting you need.

Usually, the information can be found written on your lathe station or in the manual.

If not, it can be measured easily.

See the most common mounts below.

2. LATHE CHUCKS

3-jaws or 4-jaws?

The most common lathe chucks are either 3-jaw or 4-jaw and refers

to the amount of jaws that the workpiece can be clamped with.

The shape of your workpieces decide what jaw-type is needed.

Steel or cast iron?

Steel is recommended for high speed machining eg. CNC-machines.

Cast iron is recommended for general use.

3. JAWS

Accessories for lathe chucks

A lathe chuck is delivered with 1 set of outside and 1 set of inside jaws.

If you wish to modify your own jaws, soft jaws can be purchased,

which is available in solid jaws or top jaws.

WHAT TYPE TO USE?

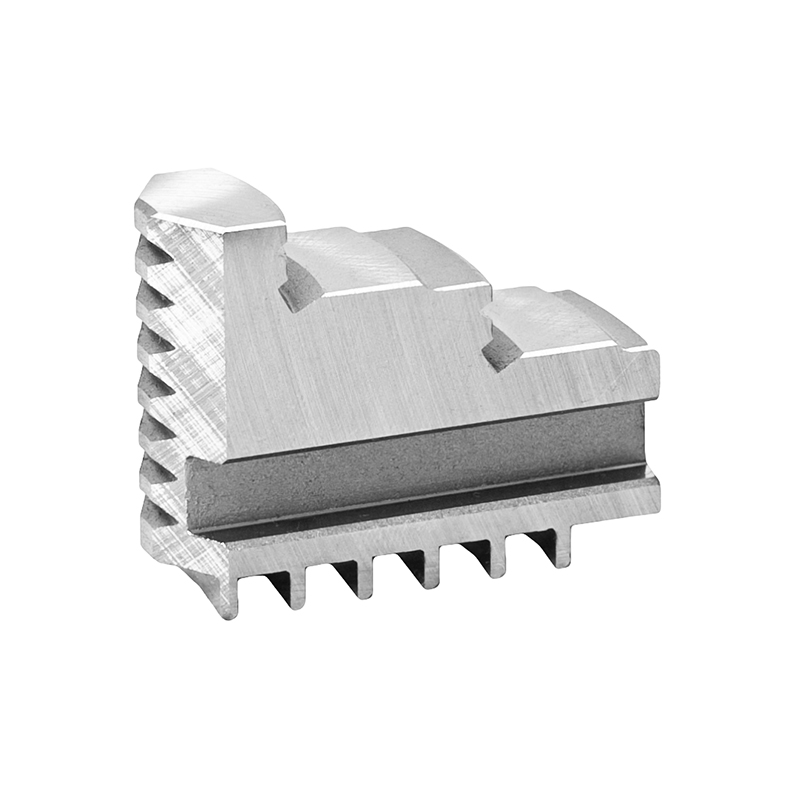

INSIDE JAWS

Inside jaws are used when the workpiece has to be held on the outside. The jaws move in towards the center and clamp on the outside of the workpiece.

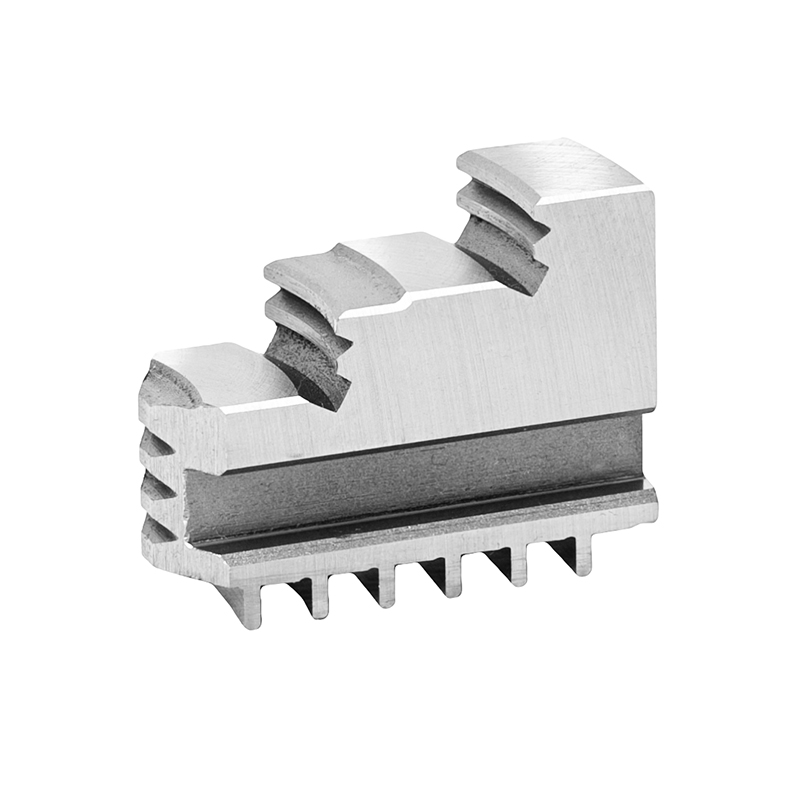

OUTSIDE JAWS

Outside jaws are used when the workpiece has to be held on the inside. The jaws move outwards from the center and clamp on the inside of the workpiece.